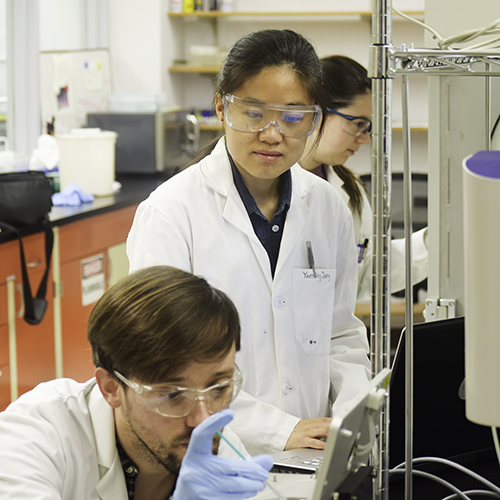

MRSEC researchers enjoy ready access to a number of multiuser instrumentation facilities at the University of Minnesota, as well as to selected equipment in individual laboratories within the College of Science and Engineering, including:

These facilities are available to UMN investigators and external academic and industrial customers. The CSE Characterization Facility, the Minnesota Nano Center, and the Polymer Characterization Facility offer a tiered user fee structure. Users from the UMN, other academic institutions, and IPRIME Visiting Scientists are charged at University rates. Students, postdocs, faculty, MRSEC summer participants, and external academic and industrial visitors have full hands-on access to the equipment after training and certification by the appropriate staff. These shared facilities create a natural environment for stimulating collaborative interactions among individuals from numerous sectors. Many of the professional staff are internationally recognized experts in their fields and formally collaborate with MRSEC investigators and individuals from other institutions.

12 Shepherd Labs

100 Union St. S.E.

Minneapolis, MN 55455

phone: 612-626-7594

email: charfac@umn.edu

The Characterization Facility ("CharFac") is a multi-user, shared instrumentation facility for materials research spanning from nanotechnology to biology and medicine.

140 Physics & Nanotechnology Building

115 Union St. SE

Minneapolis, MN, 55455

phone: 612-624-8005

email: mnc@umn.edu

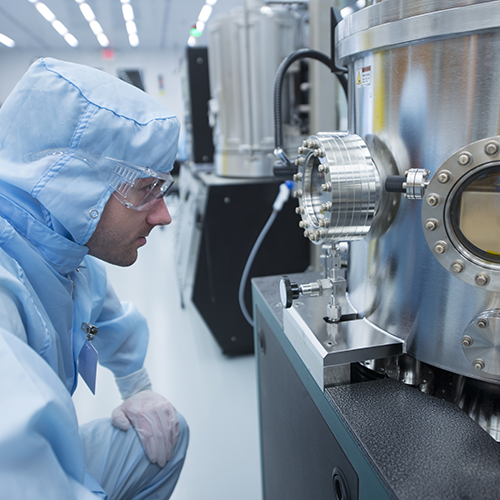

The Minnesota Nano Center (MNC) supports the fabrication, synthesis, and characterization of nanoscale devices and materials for both academic and industrial users. The lab offers all of the major pieces of processing equipment needed for top-down fabrication.

The Nano Center also offers laboratories for synthesizing and analyzing nanomaterials and for exploring biological applications of nanotechnology; tools include dynamic light scattering, optical particle tracking, cell culture equipment, fluorescence/confocal microscopy, and a state-of-the-art analytical ultracentrifuge

559 Walter Library

117 Pleasant St. SE

Minneapolis, MN, 55455

phone: 612-624-0528

email: help@msi.umn.edu

The Minnesota Supercomputing Institute has the software, hardware, and experts to provide the support you need for your research no matter what the research area. MSI Facilities Overview (Short):

Amundson Hall

421 Washington Ave SE

Minneapolis MN 55455

For more information: contact us

email: polymerchar@umn.edu

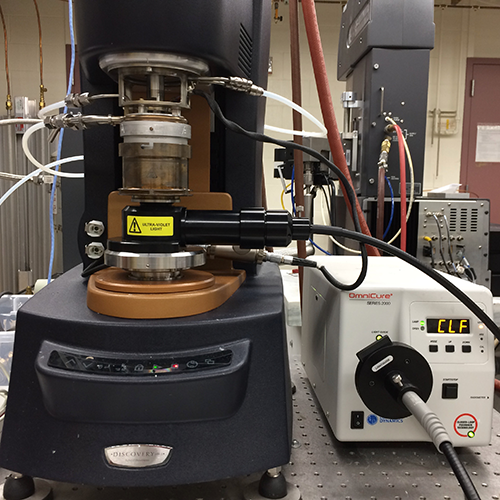

The Polymer Characterization and Processing Facility is available to University researchers and industrial clients. Assistance or collaboration is available for testing, training, and interpretation of results.

193 Kolthoff Hall

225 Pleasant St SE

Minneapolis, MN 55455

The LeClaire-Dow Instrumentation Facility house the:

These laboratories annually support hundreds of researchers in the Department of Chemistry, across the university, and from other institutions and industries.

Mass Spectrometry Laboratory instruments include:

Nuclear Magnetic Resonance Laboratory

Five NMR spectrometers:

X-Ray Crystallographic Laboratory (XCL)

The Materials Research Facilities Network is a nationwide partnership of NSF supported MRSEC centers designed to provide support to researchers in the broad area of Materials Research in academic, government and industrial laboratories around the world. The goal of the Facilities Network is to provide users with unprecedented access to instruments, techniques and collaborators in order to enhance their studies of the synthesis, characterization and theory of materials.

To inquire about possible MRFN financial support to supplement user fees for equipment and services at the University of Minnesota, email: mrsec@umn.edu.

DMR-FIRST, the Division of Materials Research Facilities and Instrumentation Research Search Tool, makes your research instrumentation findable, accessible, and fully integrated into the burgeoning network of data resources for materials research.

DMR-FIRST aims to make your life simple: update your instrumentation data in one place – either the website you already use or a website that DMR-FIRST provides – and it updates automatically everywhere else. Follow the links in the navigation bar above to learn more.

UMN MRSEC

435 Amundson Hall, 421 Washington Ave. SE, Minneapolis, MN, 55455

P: 612-626-0713 | F: 612-626-7805